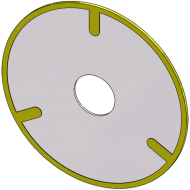

Product information

Add references for which you want a devis

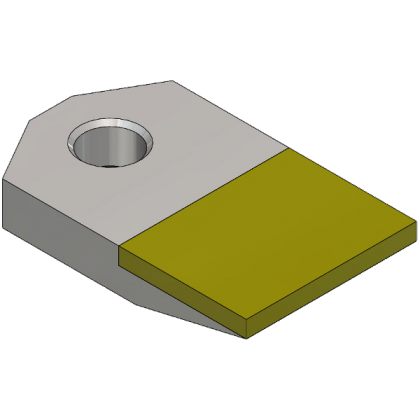

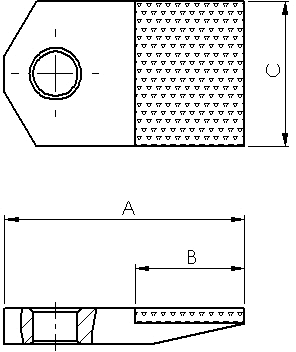

| Order reference | Grit size | Length A | Height of diamond B | Width C | |

|---|---|---|---|---|---|

| 50 3300 P2 G06 | G06 | 28 | 10 | 10 | |

| 50 3300 P2 G08 | G08 | 28 | 10 | 10 | |

| 50 3300 P2 G10 | G10 | 28 | 10 | 10 | |

| 50 3300 P2 G15 | G15 | 28 | 10 | 10 | |

| 50 3301 P2 G06 | G06 | 33 | 15 | 10 | |

| 50 3301 P2 G08 | G08 | 33 | 15 | 10 | |

| 50 3301 P2 G10 | G10 | 33 | 15 | 10 | |

| 50 3301 P2 G15 | G15 | 33 | 15 | 10 | |

| 50 3302 P2 G06 | G06 | 28 | 10 | 15 | |

| 50 3302 P2 G08 | G08 | 28 | 10 | 15 | |

| 50 3302 P2 G10 | G10 | 28 | 10 | 15 | |

| 50 3302 P2 G15 | G15 | 28 | 10 | 15 | |

| 50 3303 P2 G06 | G06 | 28 | 10 | 20 | |

| 50 3303 P2 G08 | G08 | 28 | 10 | 20 | |

| 50 3303 P2 G10 | G10 | 28 | 10 | 20 | |

| 50 3303 P2 G15 | G15 | 28 | 10 | 20 | |

| 50 3304 P2 G06 | G06 | 33 | 15 | 20 | |

| 50 3304 P2 G08 | G08 | 33 | 15 | 20 | |

| 50 3304 P2 G10 | G10 | 33 | 15 | 20 | |

| 50 3304 P2 G15 | G15 | 33 | 15 | 20 | |

| Other dimensions on request |

Complementary informations

- Bond P1 : Very good wear resistant bond

- Bond P2 : Good wear resistant bond

- Bond P3 : Usual wear resistant bond

- Bond P4 : Friable wear resistant bond

- Grain 03 : Small grain size

- Grain 07 : Fine to medium grain size

- Grain 08 : Medium grain size

- Grain 10 : Medium to coarse grain size

- Grain 12 : Coarse grain size

In overall:

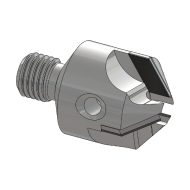

The grain dressing plate has to be fixed so that its back touches the wheel with a 30° to 40° angle. It also has to work parallel to the axis of the wheel.

A consistent cooling allow a perfect dressing and enhance the tool life.

You can adjust the roughness by modifying the feed.

Dressing infeed = 0.005 à 0.02 mm

Feed: Vd = (Ns * 0.9) / 4 with Ns = Number of rev / min of the wheel