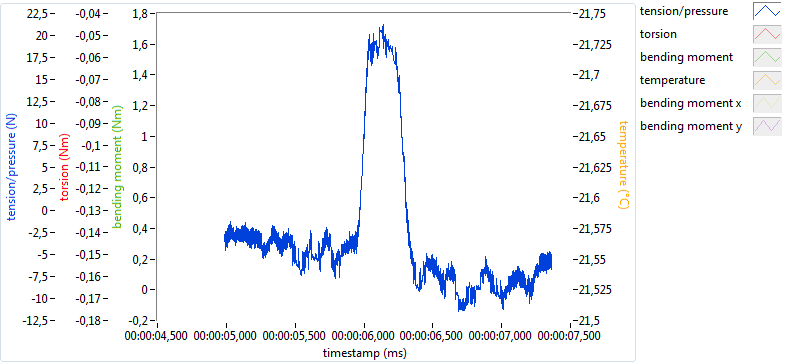

EN - Measurement drilling force evolution with full nib pcd micro-drill Ø1.78mm into CFRP.

Machining parameters on CNC Hurco BM30 at Diamoutils testing tools R&D center.

- Spindle velocity : 8000 RPM

- Feed: 480mm/mn

- VC: 45m/mn

- f: 0,06mm/U

- ap: 4mm

Drilling force measured with a sensory tool holder equipment set up on CNC milling centre Hurco BM30, drilling into curved CFRP 2.6mm thickness with a soft plastic skin on the exit side of the panel:

| Signal- mean/slope | 1st hole | 100 hole | 350 hole – | 650 hole | 850 hole | 1050 hole |

| Tension [N] | 20.2 -7,8 | 30.2 8,2 | 36.2 5,8 | 44.5 -20,1 | 48,7 -3,7 | 52.8 0,9 |

| Torsion [Nm] | -0.1 – 0,3 | -0,1 -0,1 | -0.0 -0,1 | -0.1 -0,4 | 0.0 -0,0 | -0,0 0,2 |

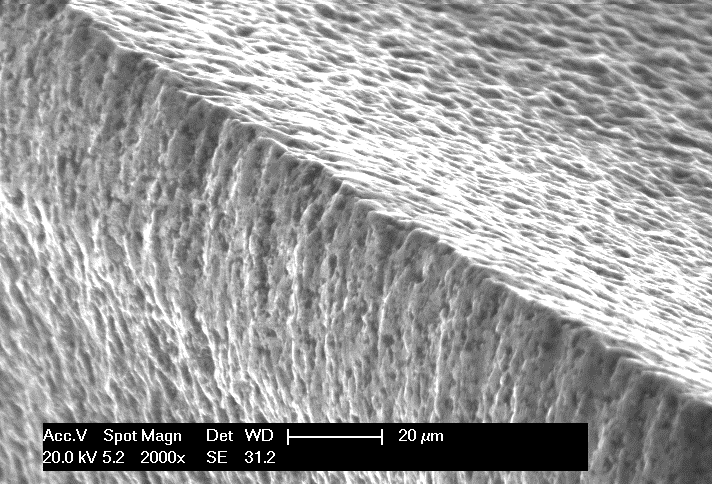

SEEM drill new with 3.2µ of preliminary edge radius.

Tension at 1st hole : 20.2 N

Tension at 1050 hole : 52,8 N

Tension evolution from 1st drilling operation and 1050 operation : + 161.3% due to preliminary wear edge cutting evolution.

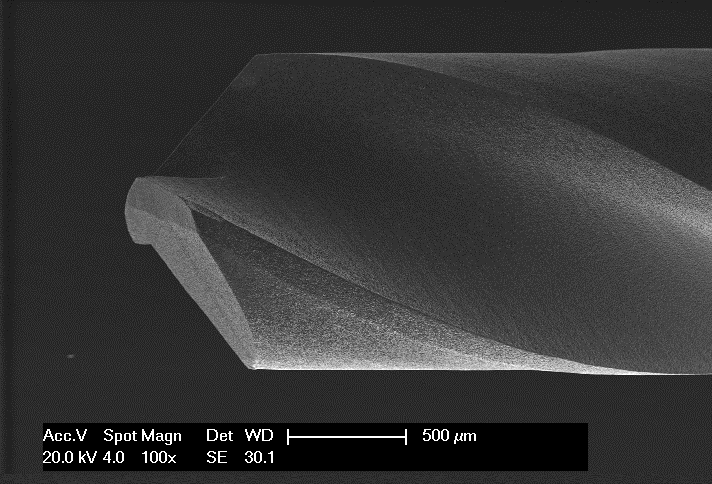

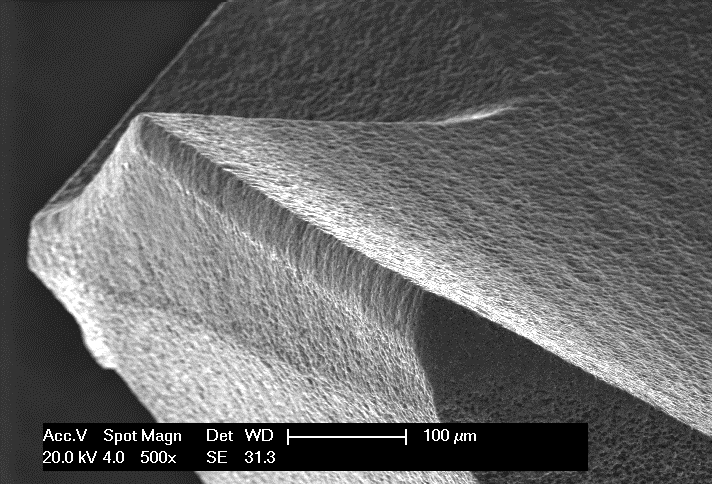

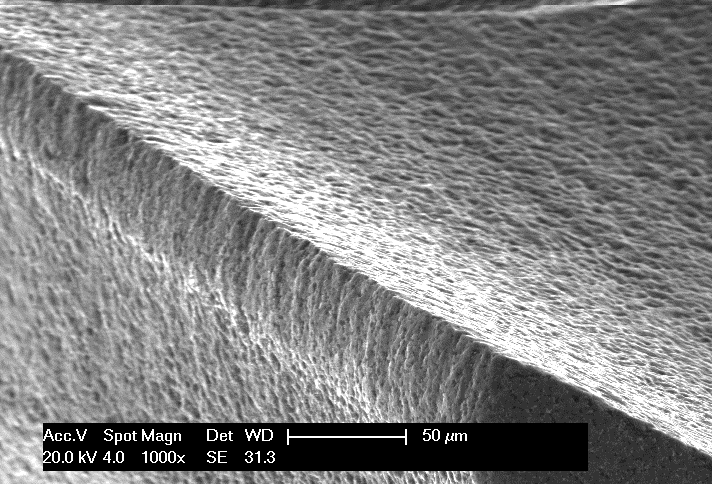

SEEM of cutting edge after 1051 drilling operations.

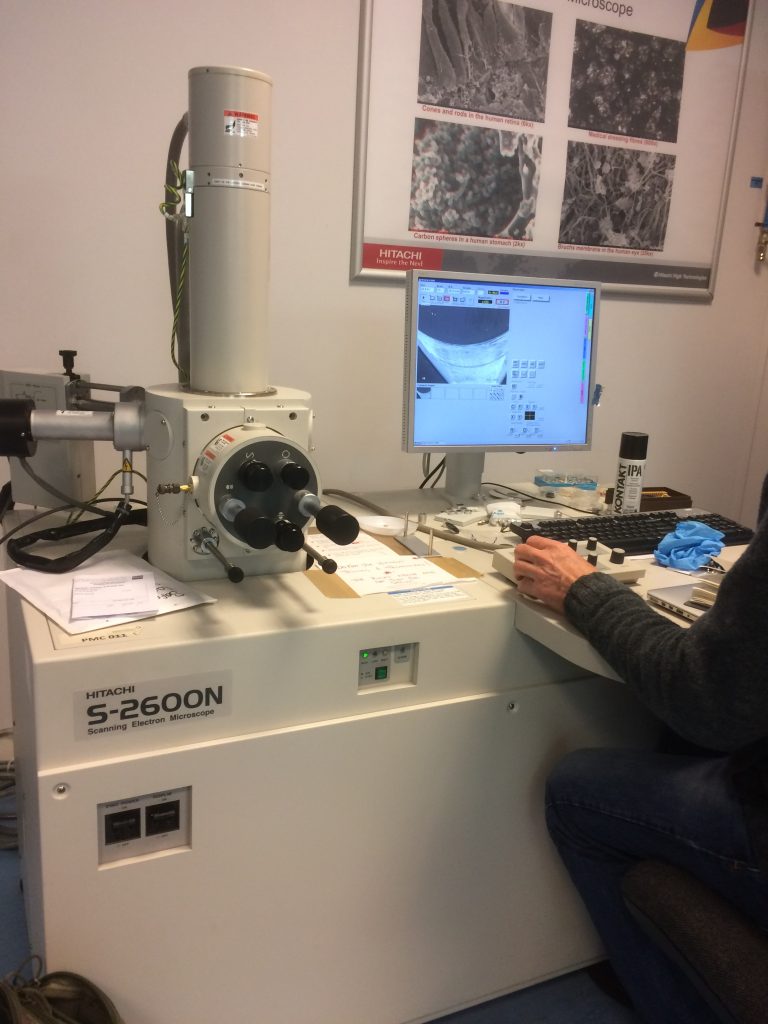

SEEM realise at UNOTT on Hitachi S2600 N.

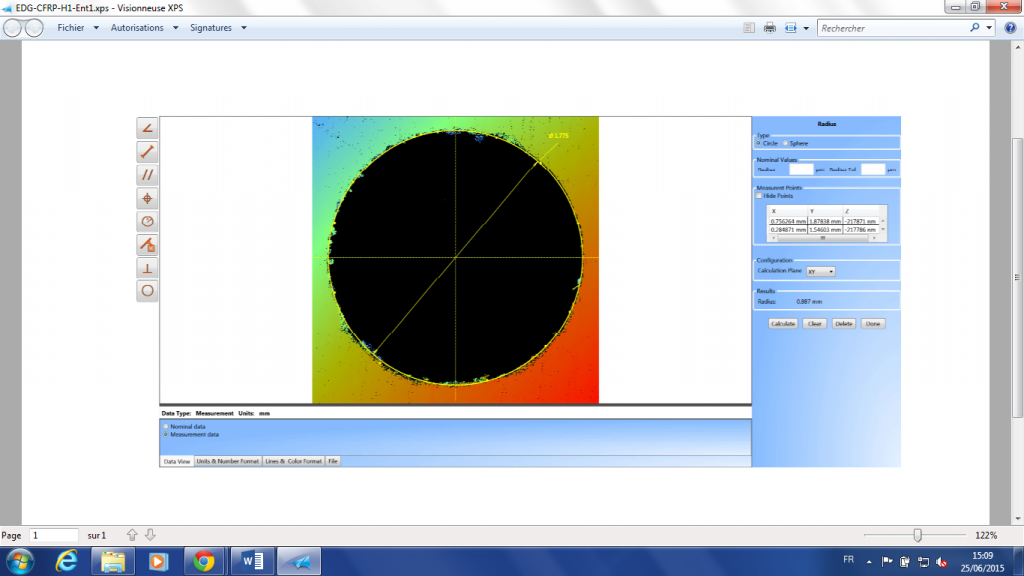

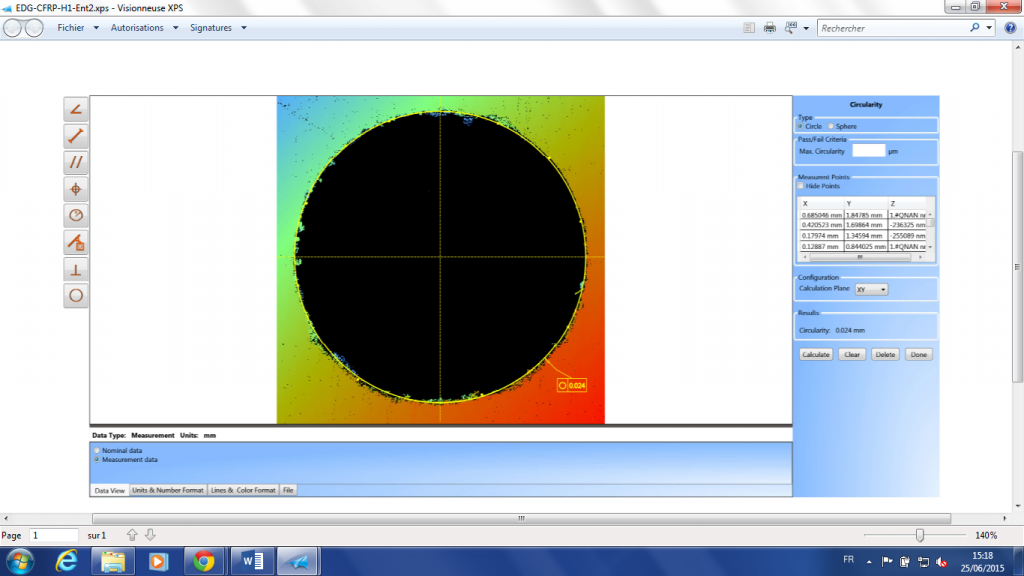

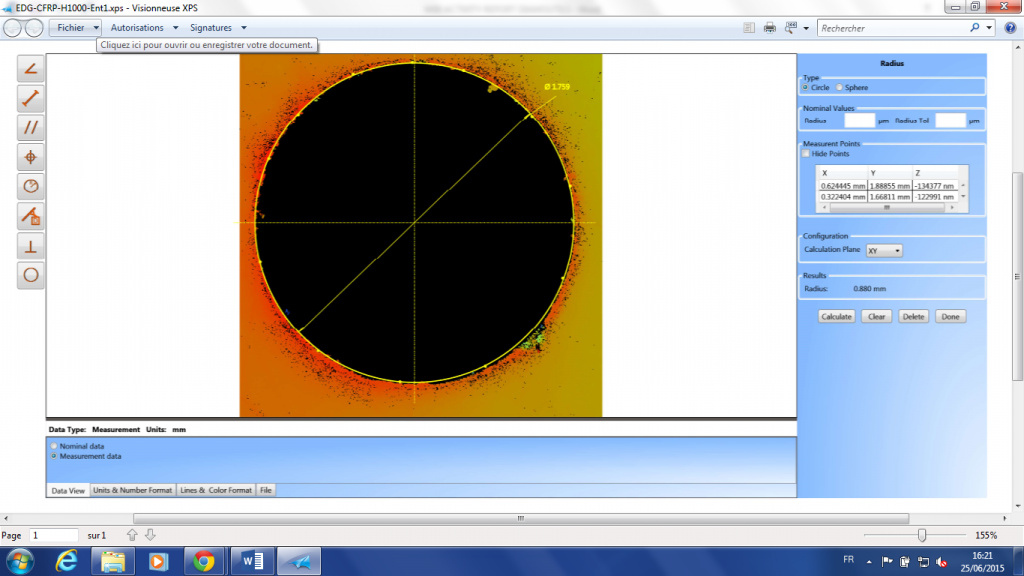

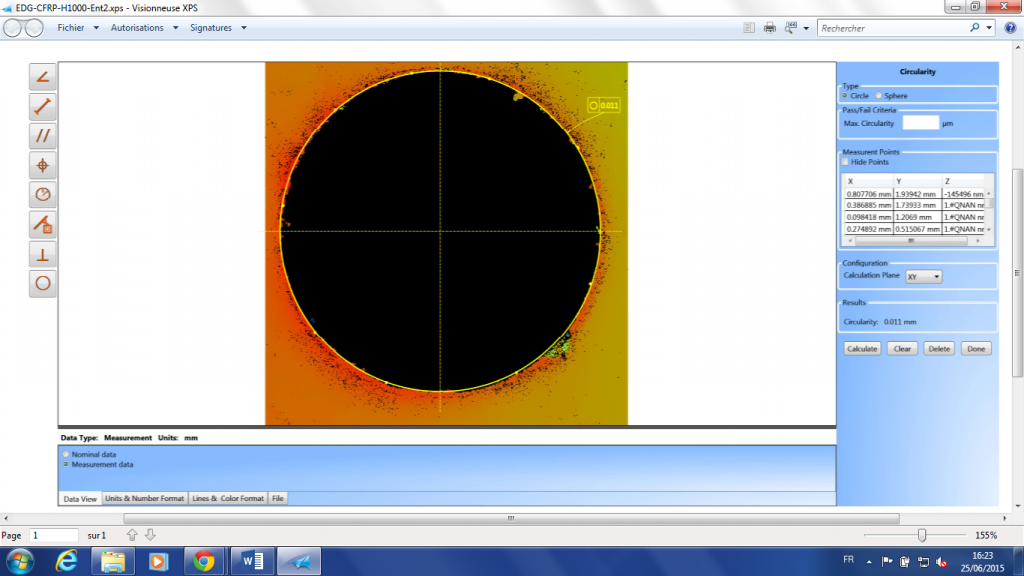

Pictures of the diameter and circularity of holes in CFRP, measured with the Bruker interferometer.

First hole, entrance side : value of diameter measured: Ø1.775 mm, value of circularity measured: 0.024 mm.

After 1000 holes entrance side : value of diameter measured: Ø1.759 mm, value of circularity measured: 0.011 mm.